Fraunhofer: Humanoid Robots Target Transport and Machine Loading

German survey shows factories want robots for goods movement, CNC machine loading, and tool handling, but safety and costs remain challenges

Humanoid robots are moving from speculative visions into industrial roadmaps, but their adoption will hinge on a delicate balance between practical utility, affordability, and workforce acceptance. A survey conducted by the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) of more than 100 German companies provides one of the clearest pictures yet of where industry sees value—and where barriers remain.

The survey spanned both large industrial players and small to medium-sized enterprises across Germany. Respondents included automotive giants such as BMW and Mercedes, as well as system integrators, control manufacturers, and end users of advanced robotics. With this breadth of input, the findings offer a representative snapshot of German manufacturing’s stance on humanoid robots.

According to the survey, 84% of companies expressed interest in humanoid robots for moving goods and operating different machines on the factory floor. Top applications included material transport, loading computer numerical control (CNC) machines, and handling power tools. These findings suggest that the expectation for humanoids is not to mimic humans perfectly, but to deliver flexible, task-oriented automation across multiple production environments.

“What we see is that humanoid robots are asked to be much more flexible than what we know from classical automation,” said Werner Kraus, head of robotics at Fraunhofer IPA. “The philosophy is to jump from one machine to the other, to detect when materials are running out, and to assist as needed.”

Interestingly, the survey also found that less than half of industrial leaders viewed legs as essential. Instead, 56% said wheels were sufficient, with far greater interest in the dexterity of robotic arms and hands. This signals a shift in focus from lifelike mobility to task-specific performance.

Industry Applications

Kraus presented the findings at the 2025 Humanoids Summit in London. His remarks underscored the practical lens through which German industry is evaluating humanoid systems, especially when compared to earlier waves of automation, such as collaborative robots (cobots).

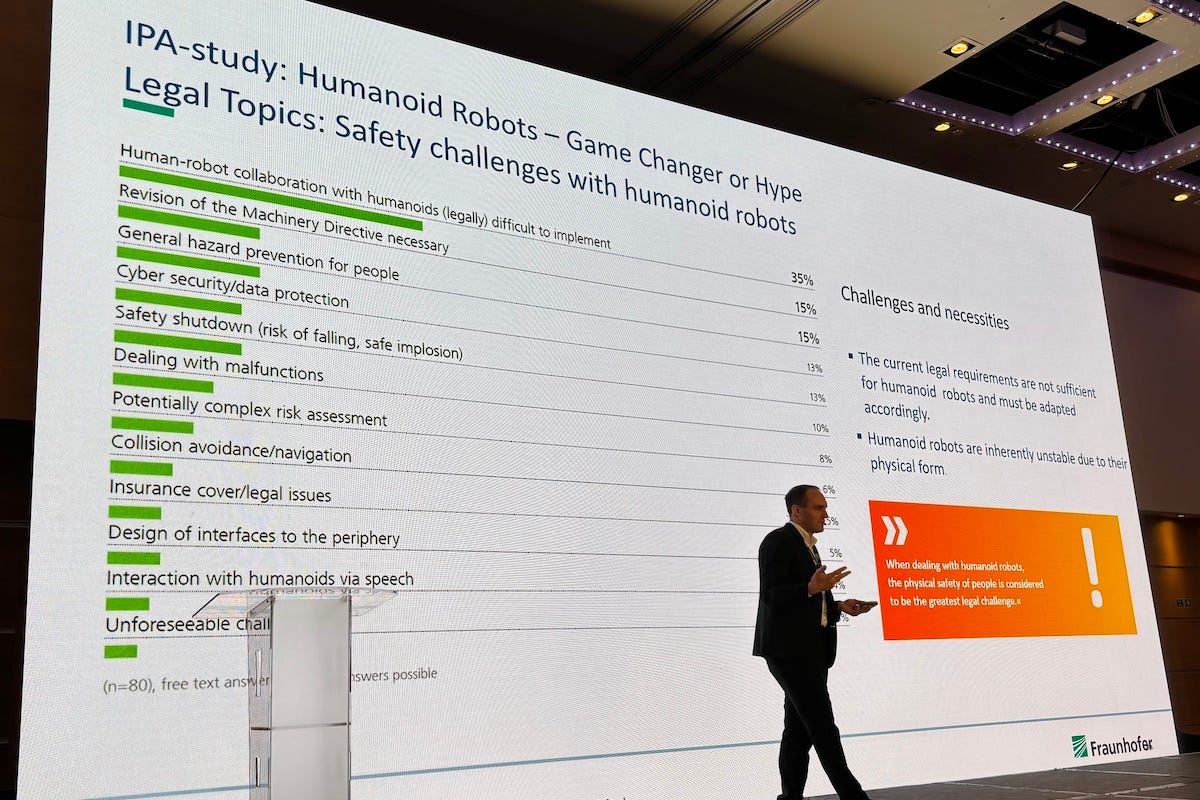

The survey revealed that safety regulation was the top concern: nearly half of respondents flagged the absence of clear standards for deploying humanoids alongside human workers.

“Almost half of the people are afraid of the non-regulated safety,” Kraus said. “We know how to deploy an industrial robot, how to deploy a cobot, but we don’t know how to deploy a humanoid in a safe way.”

Another key issue was acceptance. Kraus stressed that workforce concerns were real and visible.

“We have seen this quite regularly in our industrial projects. For example, forklift drivers are afraid that the robots are stealing their jobs,” he said.

This highlights the cultural and workforce challenges that accompany technological change, beyond the technical engineering hurdles.

Concerns around overpromising also emerged. Industry leaders recalled the early hype around cobots 15 years ago, when expectations far outstripped actual deployment. Many executives stressed the importance of managing ambition carefully, ensuring that humanoid robots are framed not as silver-bullet solutions, but as complementary tools in production ecosystems.

Cost and Timelines

Economic realism was another defining theme of the survey.

“Until a humanoid robot costs less than €100,000 and has a productivity of half a human, it’s not a case for most customers,” Kraus explained, adding that the alignment between industry expectations and current supplier pricing was “good news.”

On adoption timelines, just 6% of companies expected humanoid robots to be viable in fewer than three years. Only a small minority expected faster deployment. Executives emphasized that replacement would likely occur at natural workforce transitions, such as retirements, rather than the abrupt displacement of existing staff.

“From the perspective of our companies, they reported they see humanoid models available in the next three to ten years,” Kraus said.

The survey also asked companies which technical features they deemed most critical. Navigation and environmental awareness were prioritized, alongside the ability to detect and sort workpieces autonomously. Load carrying, operation on flat ground, and interchangeable grippers also featured heavily. Interestingly, only a small fraction of respondents called for anthropomorphic hands, with modular grippers seen as more practical in industrial settings.

Europe’s Robotics Race

Kraus also placed the discussion in a broader geopolitical context. He highlighted the European Commission’s investment of €7 billion in robotics research under the SPARC (Strategic Partnership for Robotics in Europe) program between 2014 and 2020.

Launched as a public-private partnership with the euRobotics industry association under the Horizon 2020 framework, SPARC aimed to boost European competitiveness by linking academia and industry in manufacturing, healthcare, and agriculture. It was the largest civilian robotics initiative of its time.

“Europe has already invested billions in robotics research, but today individual startups elsewhere are receiving comparable sums on their own,” Kraus said. “This shows how rapidly the competition is moving.”

At the same time, cybersecurity risks and data governance were flagged as growing concerns. As with connected consumer devices, industrial robots will generate vast streams of sensor data. German companies in particular are sensitive to where that data resides and how it is secured.

Beyond Europe’s institutional research efforts, massive private investment in humanoid robotics worldwide signals intensifying competition. One American startup recently secured hundreds of millions in funding—nearly equivalent to the entire annual research spend of some European robotics programs. Industry observers at the summit argued that Europe cannot afford to lag in commercialization, despite its strong foundation in research.

Strategy Forward

Looking ahead, Kraus argued that progress will require advancements in robotic hands, environment-aware navigation, and modular grippers, alongside robust safety frameworks. He emphasized that industry adoption cannot succeed without engaging employees in the decision to introduce humanoid robots, noting that poor rollouts in supermarkets had previously led to robots being vandalized or hidden away.

“The real game changer lies in the possibility that mobile humanoids can quickly adapt to different machines and settings,” he said. “But in the end, it is really important that we involve the workforce in the decision to go for the robot.”

Fraunhofer’s study concluded that companies are currently focused on relatively simple pick-and-place tasks but see strategic potential in mobile, flexible systems that can support complex, multi-machine workflows. The findings align with Germany’s broader industrial philosophy: scaling innovation only when it is proven safe, reliable, and socially sustainable.

With Fraunhofer’s study now publicly available, the institute is positioning itself as both a technical leader and a convener of dialogue across industry, regulators, and society. For Germany’s industrial heartland, the path forward will depend on translating scientific ambition into safe, economically viable, and socially accepted humanoid systems.