Agentic AI in Aerospace: Machines for Routine Tasks, Humans for Strategy

Agentic AI is reshaping aerospace by taking over routine inspections, data processing, and workflow management—freeing humans to lead on strategy, innovation, and long-term planning

Agentic artificial intelligence—the new generation of autonomous, decision-making systems—is reshaping aerospace faster than any prior wave of automation. No longer limited to assisting human operators, these AI agents now communicate, plan, and execute tasks independently, transforming engineering, manufacturing, and workforce management.

“The shift isn’t about replacing people with machines,” said Stuart Evans, Director of Future of Work & Digital Experience at Rolls-Royce. “It’s about giving intelligent systems the autonomy to handle repetitive or data-heavy work, so humans can focus on where judgment and creativity matter most.”

Evans described how Rolls-Royce has moved beyond conventional automation into agentic AI systems capable of coordinating inspection, design, and maintenance workflows. These technologies, he explained, can make decisions across departments, learning from experience and sharing insights with other digital agents.

“We’re now teaching AI to talk to AI,” he said. “That’s where the real efficiency comes from.”

At Rolls-Royce, thousands of engineers have been reorganized into a single enterprise-wide function to enable skill mobility and better deployment of talent. AI now handles complex data processing—such as analyzing thousands of hours of service data from aircraft engines, a task that would take humans centuries to complete.

The company has digitized the expertise of its senior engineers, making that knowledge instantly accessible to more than 14,000 staff members worldwide.

One of the most striking applications involves engine inspection. Autonomous drones can now examine jet engines after test runs in a matter of hours rather than days, capturing high-resolution imagery for human specialists to review remotely.

“This isn’t a vision of the future,” Evans emphasized. “It’s already happening in our facilities today.”

He added that Rolls-Royce is developing agentic AI for back-office coordination, where digital agents manage documentation and reporting tasks without human oversight. “The technology now handles the busywork, so our people can handle the breakthroughs.”

Beyond engineering, Rolls-Royce is exploring ways to deploy agentic AI in environmental sustainability initiatives. AI agents are being trained to optimize energy use in testing facilities, reducing emissions and waste. “Our goal is not only to make aerospace smarter but greener,” Evans said. “We see sustainability as an engineering challenge—and AI is the most powerful tool we have to meet it.”

Empowering the Workforce Through Intelligent Systems

The Royal Aeronautical Society’s President’s Conference: People in Aerospace, held in London on October 7, 2025, focused on ensuring that automation enhances rather than replaces human expertise.

Speaking alongside Evans, Mike Dwyer, Vice President and Head of Intelligent Industry UK at Capgemini UK plc, outlined how the global consulting and technology firm is helping clients integrate AI and automation responsibly.

Capgemini specializes in transforming business operations using digital tools—from AI and cloud computing to data strategy and engineering.

“We want to empower people in the aerospace industry with technology that helps them achieve more in less time, without sacrificing precision or safety,” Dwyer said.

Capgemini has introduced AI-powered learning platforms that replicate the experience of human mentorship. One system, known as “Dr Tara Singh,” uses a generative AI avatar to guide thousands of employees through on-the-job learning, blending video, structured data, and conversational interaction. The digital mentor helps recruits acquire skills faster while keeping safety at the core of every task.

“Imagine being able to train thousands of people simultaneously, each with personalized guidance,” Dwyer said. “That’s the power of intelligent learning systems.”

Capgemini also deploys predictive analytics across aerospace production lines, helping manufacturers anticipate maintenance needs and manage supply chains with near-real-time visibility. Dwyer explained that these technologies have reduced delays and improved resource allocation across global projects.

“Agentic AI lets us see problems before they exist. That’s how you scale operational intelligence,” he said.

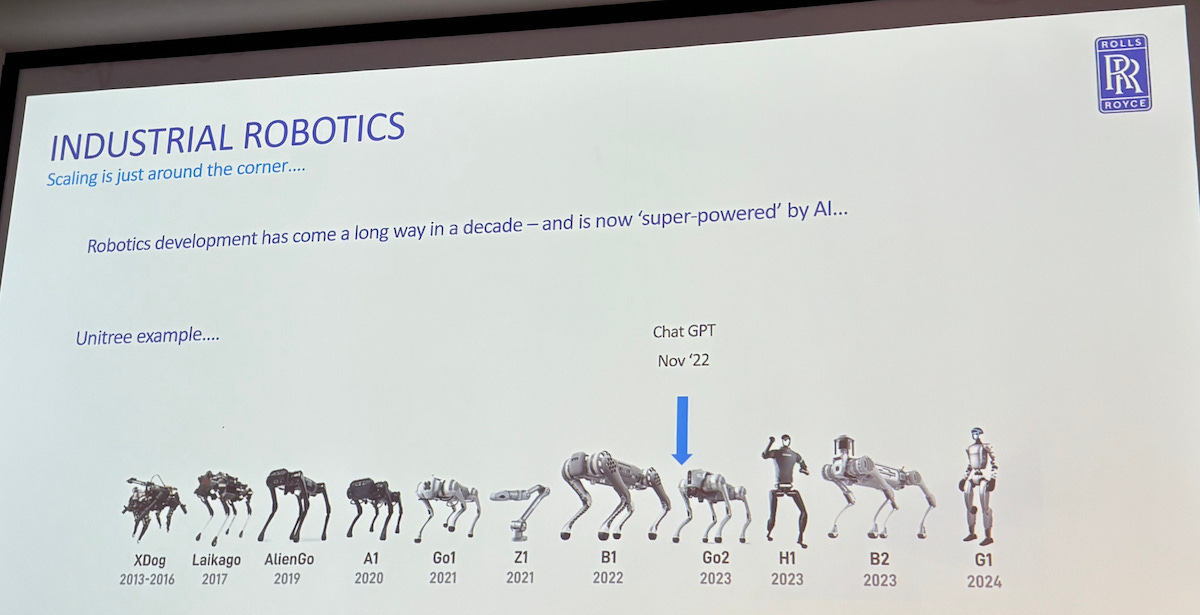

To illustrate the broader potential, Dwyer described how agentic AI could soon enable “smart factories” where robots coordinate production autonomously.

“Machines that can sense, reason, and act without instruction are no longer theory—they’re the next industrial reality,” he said. “We’re building systems that collaborate, adapt, and learn like teams of skilled engineers.”

From Creativity to Industrialization

Both speakers agreed that the United Kingdom’s competitive edge will depend on how effectively companies industrialize innovation. Dwyer summarized the challenge more constructively: “Britain has always excelled at discovery. Now our success depends on how fast we can turn discovery into delivery.”

He cited examples from other industries where AI has significantly compressed research timelines—such as pharmaceutical firms using AI to design new molecules in minutes. For the aerospace industry, similar gains can be achieved through the use of digital twins and AI-accelerated design loops. “When you let machines handle the complexity, you free humans to think bigger.”

Evans noted that Rolls-Royce engineers are already experimenting with AI-driven design simulations that can test thousands of variations in a matter of hours. “That speed lets us iterate at the pace of imagination. We’re not just faster—we’re smarter.”

He added that collaboration between academia and industry would be crucial to scaling this innovation.

“We’re partnering with universities and startups to explore safe, explainable AI,” Evans said. “Aerospace has to set the gold standard for responsible use.”

Trust, Transparency, and the Human Element

Despite the promise, both speakers acknowledged public concern about automation and job displacement. Evans said that transparency and engagement are key: “AI will take some jobs, but it will create many more. The challenge is preparing people for those new roles and building trust along the way.”

Dwyer stressed that leadership must be hands-on with the technology.

“If executives aren’t using AI themselves, they can’t lead through it,” he said. “You have to model confidence, not just talk about it.”

Both emphasized that accountability must remain a human-centered approach.

“Automation can do the work,” Dwyer noted, “but humans must define what good looks like.”

Evans added that the future of aerospace will depend on designing AI systems that remain auditable and explainable. “If you can’t explain it, it doesn’t belong in engineering.”

Robots and the Future of Aerospace

Looking ahead, both companies foresee agentic AI expanding across the aerospace ecosystem—from predictive maintenance to air traffic management and immersive training simulations. These emerging systems will collaborate with humans to optimize design, safety, and operational decision-making at an unprecedented scale.

Evans predicted that humanoid robots guided by AI agents could soon perform precision assembly in aerospace facilities.

“In the next five years, you’ll see intelligent machines that can work side by side with people,” he said. “They’ll handle precision assembly, inspection, and testing—while humans focus on creativity, ethics, and decision-making.”

Dwyer envisioned AI copilots that support engineers during testing and simulation, allowing faster design certification cycles and more resilient aircraft systems.

“We’re entering a world where human and machine decision-making are intertwined,” he said. “That collaboration is what will define the next generation of aerospace breakthroughs.”

As the sector embraces these transformations, experts agree that agentic AI will drive more than productivity—it will redefine innovation itself. By merging human judgment with machine precision, aerospace organizations are laying the groundwork for safer flights, sustainable production, and smarter global operations.

In the years ahead, this synergy is expected to shape not just how aircraft are built, but how the entire industry thinks, learns, and evolves.